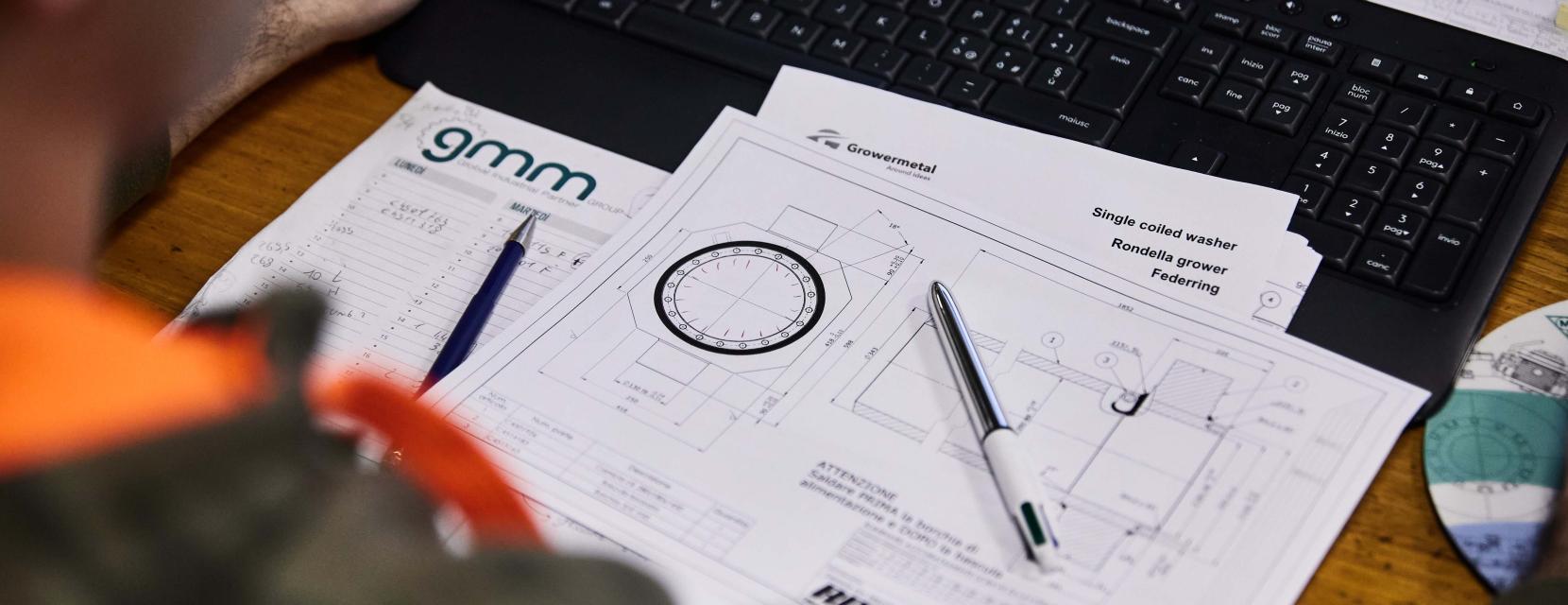

Before the turning machine and milling machine, there is a studied and simulated design.

We are down-to-earth people with a passion for jobs well done. We let our products speak for themselves, because we believe that a perfect component can explain more than a thousand words. But design is a different kettle of fish, and it's important to give you an idea of the support we can provide you when you cross the RM threshold.

The art of designing is a challenge that pushes us every day to give our best. There are infinite spaces for our creativity and ability to manufacture ever more complex and innovative solutions.

The engineering department, equipped with eight people and five CAD workstations with SolidWorks, represents a powerful tool for the design and production of high-precision mechanical components.

The know-how of our engineers is the spark that ignites the 3D design engine, with which we create highly detailed models, simulate complex part assemblies, and verify product performance before starting production.

Errors are detected immediately and promptly corrected. Production costs are reduced, and the quality of the final product is improved. The ability to quickly create virtual prototypes accelerates product development time and optimizes design with efficiency.